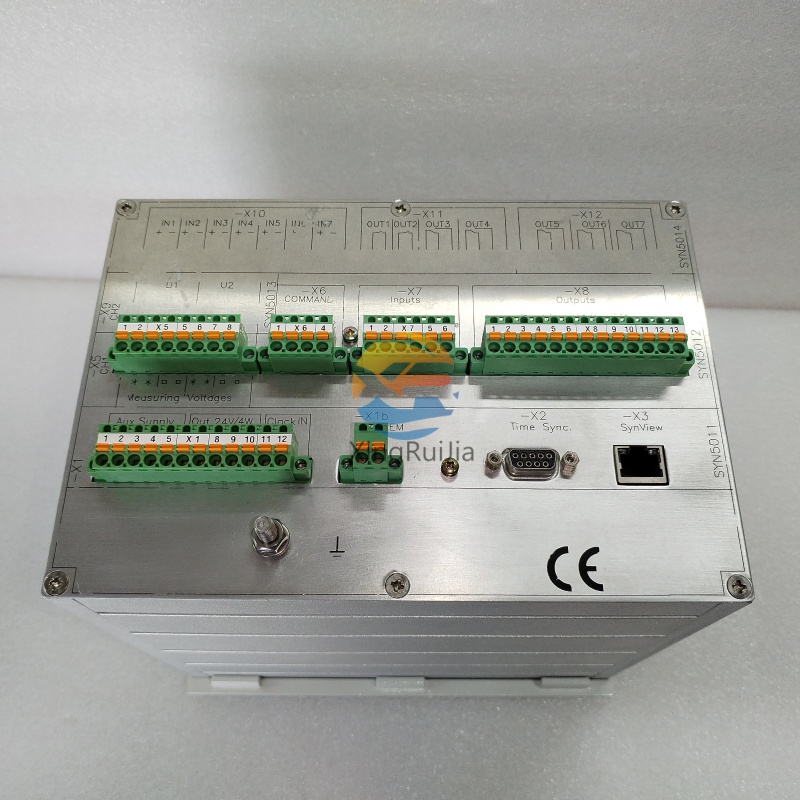

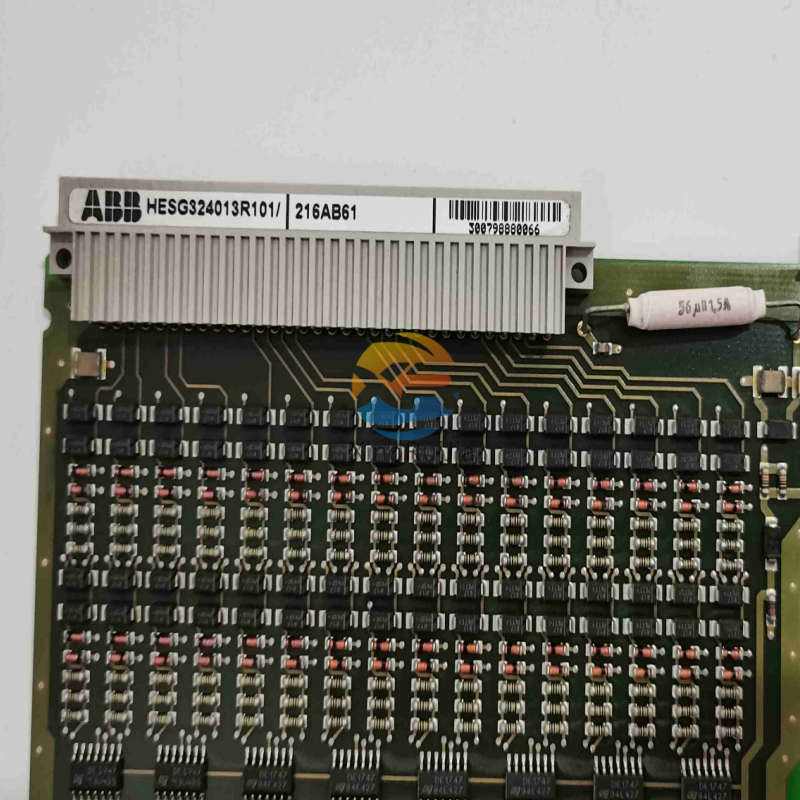

ABB DCF1061134R0001 YPP110A Application Controller - Product Details & Technical Guide

Product Overview

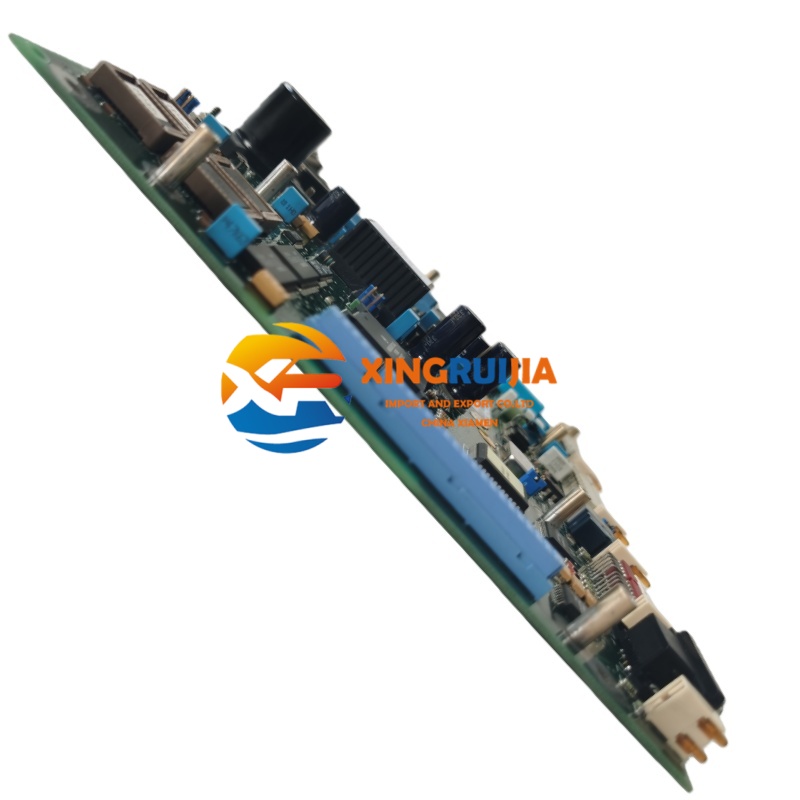

The ABB DCF1061134R0001

YPP110A Application Controller is an advanced controller specifically engineered for industrial automation and process control. As a core component of ABB's

YPP110A series, this controller combines superior performance, reliable operation, and flexible configurability, making it suitable for a wide range of demanding industrial environments. The model designation DCF1061134R0001 identifies a specific hardware version and configuration, ensuring users receive a product that complies with stringent industrial standards.

Technical Specifications & Features

Core Parameters

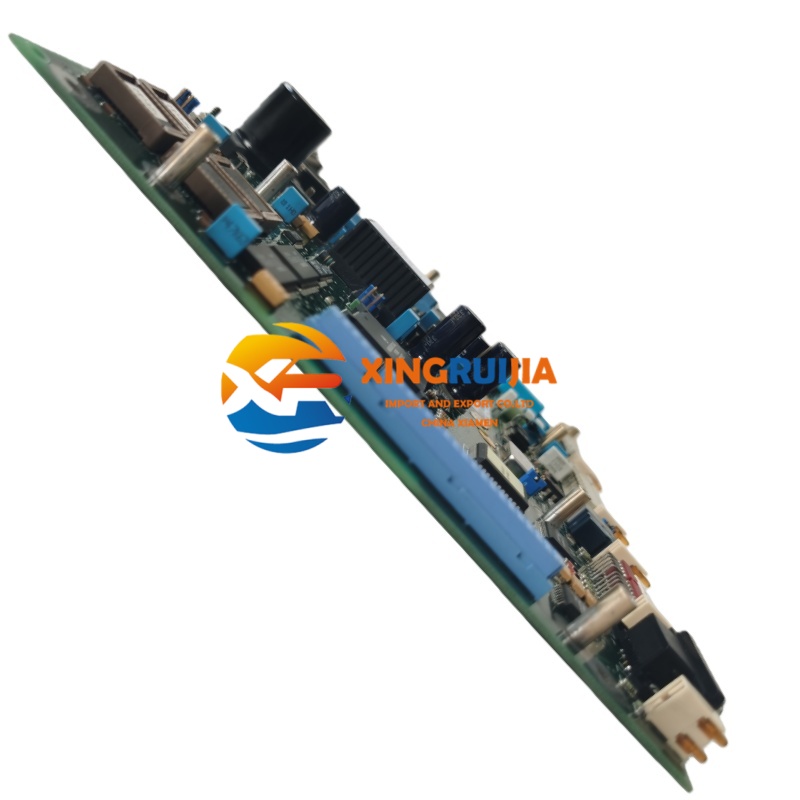

- **Processor Architecture**: High-performance 32-bit microprocessor optimized for real-time control tasks

- **Memory Configuration**: Integrated flash memory and RAM supporting complex control logic and data storage

- **Operating Temperature Range**: -20°C to +70°C, suitable for extreme industrial conditions

- **Power Requirements**: 24V DC (±20%), compliant with industrial standard power configurations

- **Protection Rating**: IP20, designed for installation inside control cabinets

Communication Capabilities

The

YPP110A controller is equipped with comprehensive industrial communication interfaces:

- **Ethernet Port**: Supports standard industrial protocols including Modbus TCP/IP and PROFINET

- **Serial Communication**: RS-232/RS-485 interfaces for legacy device connectivity

- **Fieldbus Integration**: Expandable modules supporting major fieldbus systems like Profibus and DeviceNet

Processing Performance

- **Scan Cycle**: Millisecond-level control cycles ensuring rapid response

- **I/O Processing Capacity**: Supports up to 1024 digital and 512 analog I/O points

- **Task Management**: Multi-tasking operating system with priority scheduling and event triggering

Application Areas

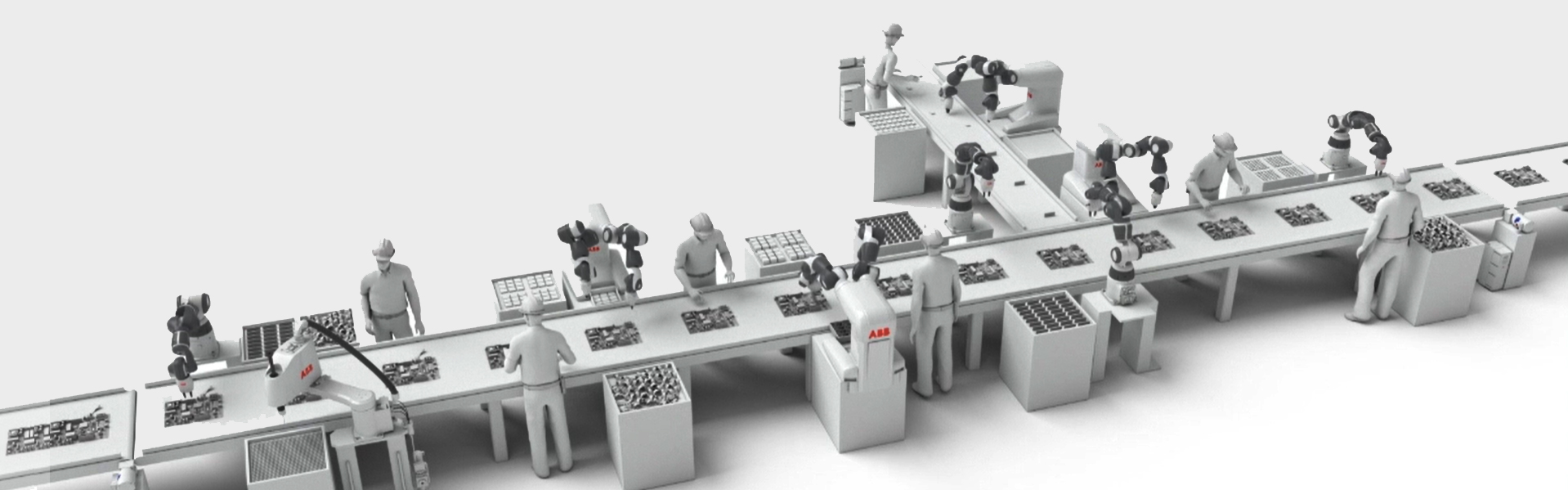

Industrial Automation

The DCF1061134R0001

YPP110A controller excels in the following automation scenarios:

- **Production Line Control**: Synchronization of robotic arms, conveyors, and processing stations

- **Packaging Machinery**: Control of high-speed, precision packaging processes

- **Assembly Systems**: Management of sequence and logic control in complex assembly processes

Process Control

In continuous and batch processing applications, this controller provides:

- **PID Control**: Precise algorithms for temperature, pressure, and flow control

- **Recipe Management**: Storage and execution of multiple production recipes

- **Data Logging**: Real-time collection of process data for quality analysis and optimization

Infrastructure Management

- **Building Automation**: HVAC systems, lighting control, and energy management

- **Water Treatment Systems**: Pump station control, water quality monitoring, and flow regulation

- **Power Monitoring**: Distribution system status monitoring and load management

Programming & Configuration

Software Development Environment

ABB provides powerful programming tools for the

YPP110A series:

- **IEC 61131-3 Compliance**: Supports multiple programming languages including Ladder Diagram (LD), Function Block Diagram (FBD), and Structured Text (ST)

- **Engineering Software**: Intuitive configuration interface simplifying project development and debugging

- **Simulation Functionality**: Offline testing of control logic reducing on-site commissioning time

Configuration Flexibility

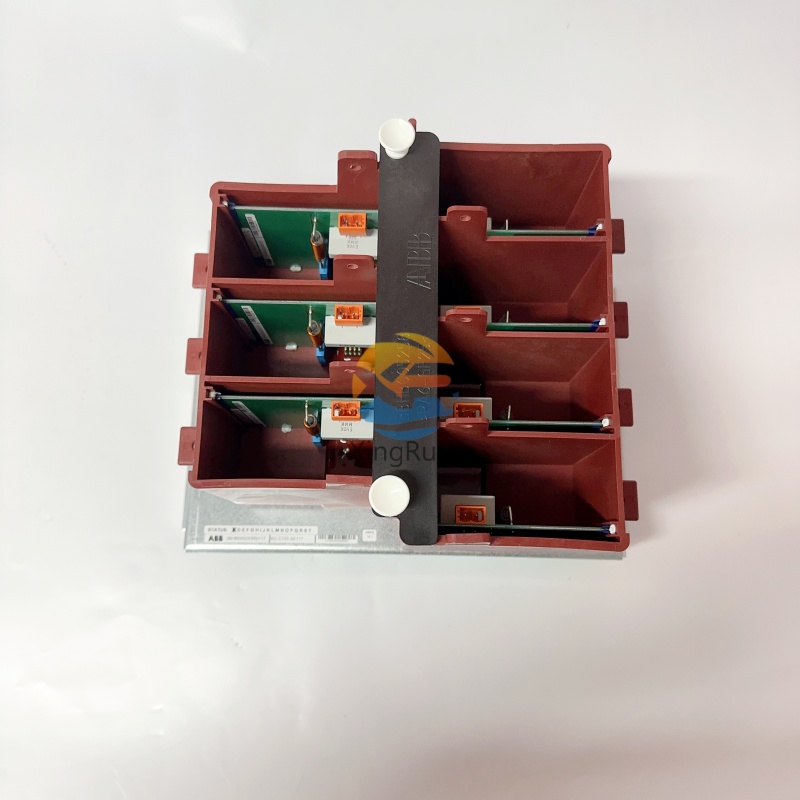

- **Modular Design**: Ability to add specialized function modules based on application requirements

- **Library Functions**: Extensive pre-defined function blocks accelerating development processes

- **User Privilege Management**: Multi-level access control ensuring system security

Installation & Maintenance

Installation Guidelines

1. **Mechanical Installation**: Standard DIN rail mounting with adequate space for heat dissipation

2. **Electrical Connections**: Follow wiring diagrams ensuring correct power and signal connections

3. **Environmental Considerations**: Avoid environments with dust, corrosive gases, and severe vibration

Maintenance Essentials

- **Regular Inspection**: Recommended every 6 months to check connection status and heat dissipation

- **Firmware Updates**: ABB regularly releases firmware updates to enhance performance and security

- **Backup Strategy**: Regular backup of programs and data preventing accidental loss

Compatibility & Integration

Integration with ABB Ecosystem

The DCF1061134R0001 controller seamlessly integrates with ABB's extensive automation products:

- **Human-Machine Interface (HMI)**: Direct connection to ABB CP600 series operator panels

- **Drive Systems**: Deep integration with ACS series frequency converters for motion control

- **Safety Systems**: Integration with ABB safety relays and light curtains for complete safety solutions

Third-Party Device Connectivity

- **Standard Protocol Support**: IT/OT convergence through OPC UA and MQTT

- **Legacy Device Interfaces**: Support for multiple traditional protocols protecting existing investments

- **Cloud Connectivity**: Optional modules enabling data upload to cloud platforms

Advantages & Value Proposition

Reliability Advantages

- **Industrial-Grade Components**: All components comply with industrial lifespan standards

- **Redundancy Functions**: Support for power and communication redundancy configurations

- **Fault Diagnostics**: Comprehensive self-diagnostic and remote diagnostic capabilities

Economic Benefits

- **Reduced Engineering Costs**: Standardized programming environment and reusable code libraries

- **Minimized Downtime**: Rapid fault diagnosis and modular replacement design

- **Energy Efficiency**: Intelligent power management and load control functions

Future Adaptability

- **Scalable Architecture**: Flexible system expansion as production needs evolve

- **Technology Update Path**: ABB provides clear product upgrade roadmaps

- **Cybersecurity**: Continuously updated security features addressing emerging threats

Ordering Information & Technical Support

Model Number Analysis

- **DCF1061134R0001**: Specific hardware version identifier

- **

YPP110A**: Series name indicating application controller category

- **R0001**: Revision number representing latest product improvements

Support Access

ABB provides comprehensive support for the DCF1061134R0001

YPP110A controller:

- **Technical Documentation**: Complete product manuals, application guides, and certificates

- **Online Resources**: ABB mySupport portal providing latest software and documentation

- **Professional Services**: Global technical support network and field service teams

Industry Certifications & Standard Compliance

This controller complies with the following international standards and certifications:

- **CE Marking**: Conforms to EU safety, health, and environmental requirements

- **UL Certification**: Meets North American safety standards

- **Industrial Standards**: Compliance with relevant IEC and ISO industrial automation standards

- **EMC Compatibility**: Meets electromagnetic compatibility requirements for industrial environments

Conclusion

The ABB DCF1061134R0001

YPP110A Application Controller represents an optimal balance of mature and innovative industrial control technology. Its robust design, powerful processing capabilities, and flexible configuration options make it an ideal choice for diverse industrial applications. Whether for simple machine control or complex process automation systems, this controller delivers reliable and efficient control solutions.

As Industry 4.0 and digital transformation advance, the DCF1061134R0001 YPP110A controller not only meets current automation needs but also establishes a solid foundation for future intelligent upgrades. Its openness and scalability ensure long-term investment value, while ABB's global service network provides support throughout the system's entire lifecycle.

For enterprises seeking to enhance production efficiency, optimize process control, and achieve digital transformation, the ABB DCF1061134R0001

YPP110A Application Controller represents a trustworthy technological choice.

CUSTOMERS WHO PURCHASED THIS PRODUCT ALSO VIEWED THESE PRODUCTS:

Sweden

Sweden

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)